Introduction

Aluminum is a lightweight, versatile metal that has become a popular choice for various marine applications, from boat hulls to equipment. However, when exposed to saltwater, aluminum faces unique challenges that can lead to corrosion and deterioration. Understanding how to protect aluminum from saltwater is essential for anyone looking to extend the lifespan of their aluminum products in marine environments.

Understanding Aluminum and Saltwater

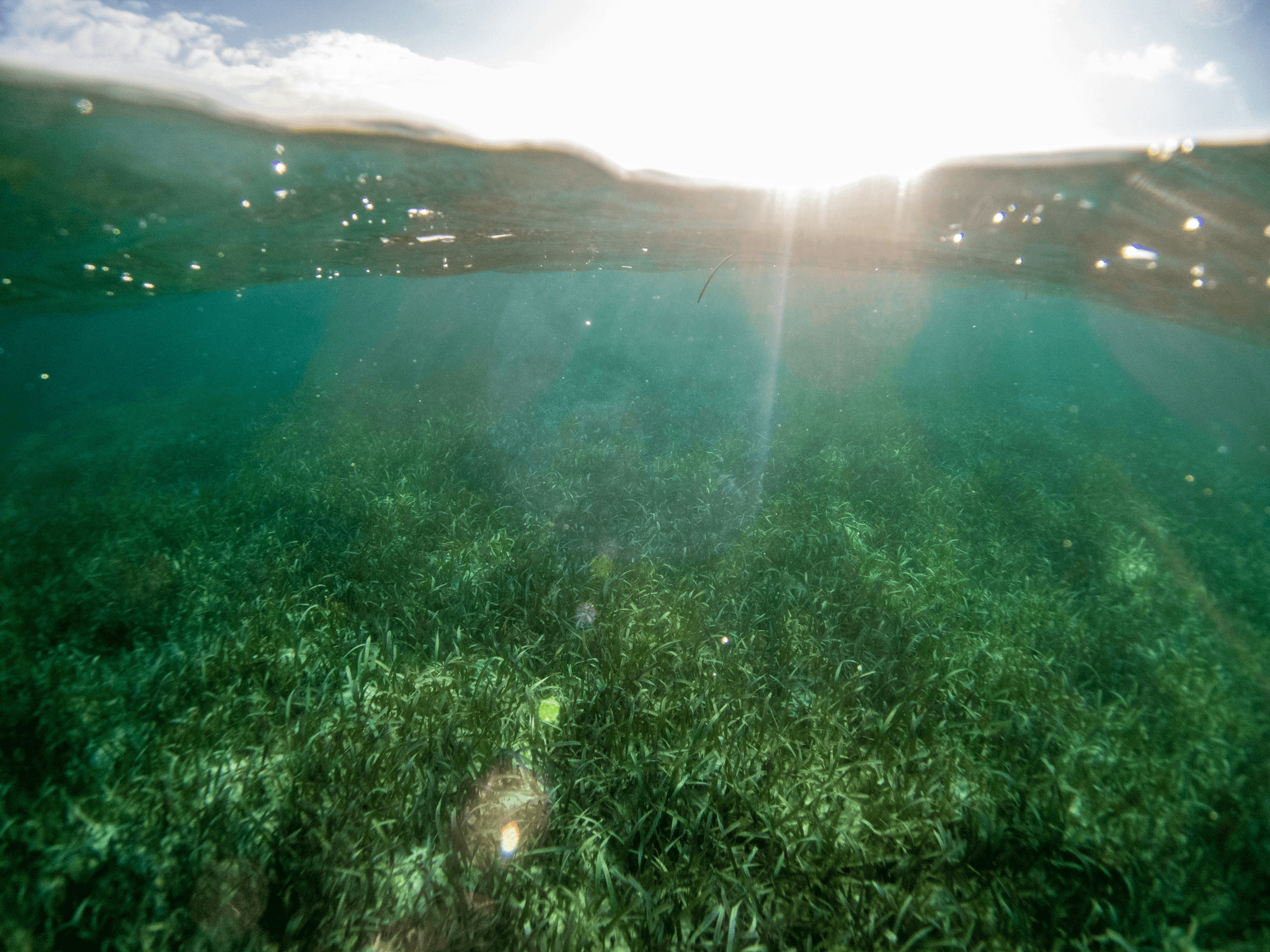

When it comes to aluminum and saltwater, the interaction can be quite complex. Saltwater is more corrosive than freshwater due to its higher conductivity and the presence of chloride ions, which can accelerate corrosion processes. This raises the question: can aluminium withstand salt water? While it can resist some degree of corrosion thanks to its protective oxide layer, prolonged exposure without proper protection can lead to significant damage.

The Importance of Protection

Protecting aluminum from saltwater is crucial for maintaining its integrity and performance over time. Without adequate protection measures in place, even high-quality aluminum can succumb to pitting and galvanic corrosion, significantly reducing its lifespan. Therefore, knowing how do you protect metal from salt water becomes vital for boat owners and manufacturers alike who want their investments to last.

Common Misconceptions About Aluminum

Many people believe that aluminum is impervious to corrosion simply because it’s a metal; this couldn't be further from the truth! One common misconception is that all types of aluminum are equally resistant to saltwater exposure—this isn’t true as alloy composition plays a significant role in durability. Additionally, questions like How long do aluminum cans last in saltwater? often arise; while they may survive short-term exposure due to their thinness and coating, long-term immersion will undoubtedly lead them down the path of decay without proper care and maintenance.

The Basics of Corrosion

Corrosion is a natural process that affects many metals, including aluminum, especially when exposed to harsh environments like saltwater. Understanding how aluminum reacts in these conditions is crucial for anyone looking to maintain their marine equipment or structures. This section will delve into what happens to aluminum in saltwater, whether it can withstand such an environment, and the various types of corrosion that can affect it.

What Happens to Aluminum in Saltwater

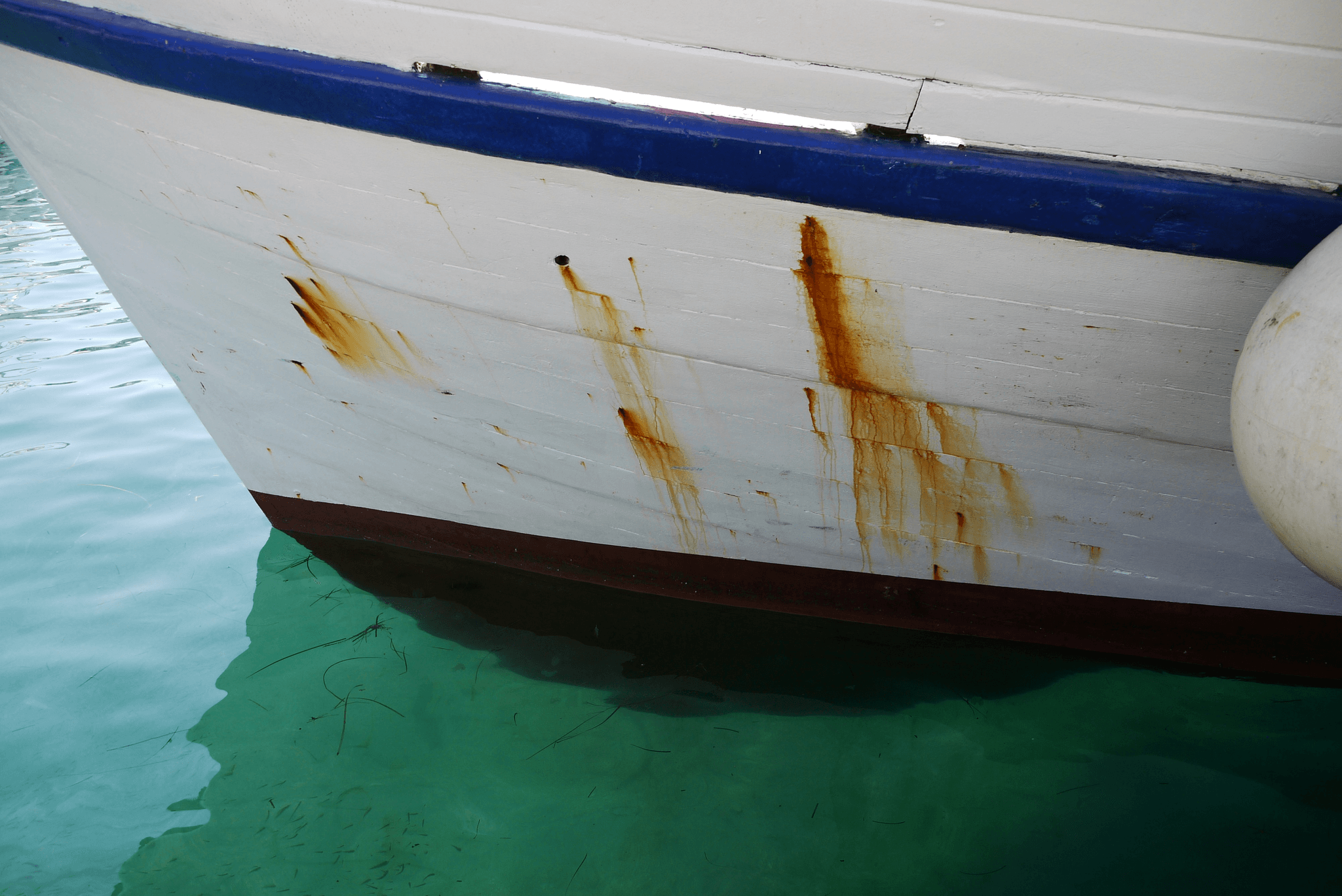

When aluminum comes into contact with saltwater, a chemical reaction occurs that can lead to its deterioration over time. The presence of salt accelerates the corrosion process by creating an electrolyte solution that facilitates the transfer of electrons between metal surfaces and their surroundings. This results in pitting and surface degradation, making it essential for boat owners and marine enthusiasts to understand how to protect aluminum from saltwater effectively.

The interaction between aluminum and saltwater can lead to significant structural damage if left unaddressed. Factors such as water temperature, salinity levels, and exposure duration all play crucial roles in determining how quickly corrosion will set in. Knowing how long aluminum cans last in saltwater helps gauge the material's durability under similar conditions.

Can Aluminium Withstand Salt Water?

The question Can aluminium withstand salt water? often arises among those considering using this metal for marine applications. While aluminum is known for its lightweight properties and strength, it is not immune to corrosion when exposed to saline environments without proper protection measures in place. Therefore, while some grades of aluminum are more resistant than others, effective protective coatings are necessary for ensuring longevity.

To truly assess whether your aluminum items can endure life at sea or near salty bodies of water requires understanding both the type of alloy used and any protective measures taken beforehand. For instance, anodized or coated aluminum may offer better resistance against corrosive elements compared to untreated varieties. Hence, exploring options on how to protect metal from salt water becomes imperative for maintaining structural integrity.

Types of Corrosion Affecting Aluminum

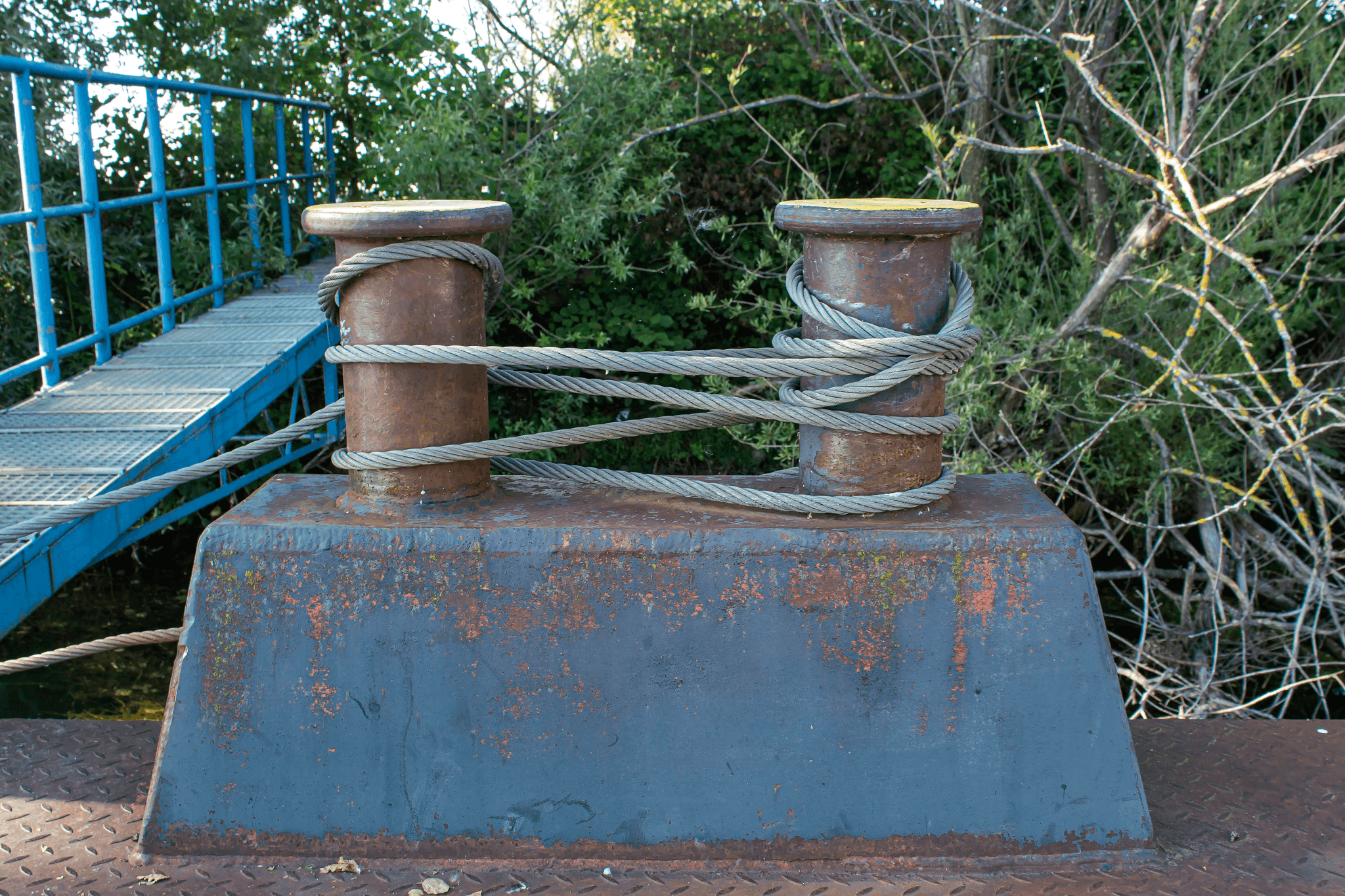

Aluminum faces several types of corrosion when subjected to salty environments—each requiring different strategies for prevention and management. Pitting corrosion is one common issue where small pits form on the surface due to localized electrochemical reactions; this type can severely weaken structural components over time if not addressed promptly. Additionally, galvanic corrosion occurs when dissimilar metals come into contact with each other while submerged or wet; this situation often leads to accelerated deterioration.

Another form worth mentioning is crevice corrosion which typically happens in confined spaces where moisture gets trapped alongside salts—think bolts or joints on boats! Understanding these various types equips you with knowledge on how do you neutralize salt corrosion on aluminum effectively before they escalate into more significant problems down the line.

In summary, being proactive about recognizing these forms of corrosion enables boat owners and marine enthusiasts alike not only safeguard their investments but also prolong their lifespan significantly through proper maintenance techniques and protective measures.

Effective Protective Coatings

Using Marine Paints and Sealants

Marine paints and sealants are specifically formulated to withstand harsh marine conditions, making them an excellent choice for protecting aluminum. When looking at how to protect aluminum from saltwater, these products create a robust barrier that prevents direct contact between the metal and corrosive elements in saltwater. Regular application of quality marine paint can effectively neutralize salt corrosion on aluminum, ensuring your boats and equipment remain in top shape.

Choosing the right type of marine paint is crucial; options range from epoxy-based paints that offer superior adhesion and durability to polyurethane paints that provide excellent UV resistance. A well-applied sealant can further enhance protection by sealing small gaps where moisture might accumulate, thus preventing corrosion from taking hold. Remember, proper preparation before application is key—cleaning surfaces thoroughly will ensure optimal adhesion and longevity.

The Role of Anodizing in Protection

Anodizing is another powerful method for enhancing aluminum's resistance to corrosion, especially in salty environments. This electrochemical process creates a thick oxide layer on the surface of aluminum, effectively shielding it against corrosive agents found in saltwater. If you’re wondering how long do aluminum cans last in saltwater, anodized surfaces significantly increase their lifespan by providing an additional level of protection.

The beauty of anodizing lies not just in its protective qualities but also its ability to retain the natural look of aluminum while adding vibrant colors if desired. This process helps prevent pitting and other forms of corrosion that could compromise structural integrity over time. For those serious about longevity, incorporating anodized components into your marine applications is a smart move when considering how do you protect metal from salt water.

Best Products for Coating Aluminum

When selecting products for coating aluminum, it's essential to choose high-quality options designed specifically for marine use. Some top contenders include Interlux Perfection Plus Marine Paint and Awlgrip Topcoat; both offer exceptional durability against UV rays and salt exposure while being easy to apply with proper preparation techniques. For those looking into sealants, 3M 5200 or Sikaflex 291 are popular choices known for their strong bonding capabilities.

In addition to these coatings, consider investing in sacrificial anodes as part of your overall strategy on how to protect aluminum from saltwater; they work alongside protective coatings by sacrificing themselves to prevent corrosion on more critical components like hulls or engines. Regular maintenance checks will ensure these products continue performing optimally over time—after all, prevention is better than cure!

Maintenance Techniques for Longevity

Regular Cleaning and Inspections

One of the most effective ways to protect aluminum from saltwater is through consistent cleaning and inspections. Rinsing off salt deposits after exposure to seawater can significantly reduce the risk of corrosion. Additionally, regular inspections help identify early signs of damage or wear, allowing you to address issues before they escalate.

When inspecting your aluminum structures or vessels, focus on areas where water may accumulate or where there are scratches in the coating. These spots are often more vulnerable and can harbor salt deposits that contribute to corrosion over time. By incorporating cleaning into your routine—think of it as a spa day for your metal—you'll ensure that your aluminum remains resilient against the elements.

How Do You Neutralize Salt Corrosion on Aluminum?

If you notice signs of salt corrosion on your aluminum surfaces, acting quickly is essential for restoration. The first step in neutralizing salt corrosion involves creating a mixture of water and mild detergent; this helps lift away corrosive salts without damaging the metal itself. Scrubbing gently with a soft brush will aid in removing any stubborn buildup while being gentle enough not to scratch the surface.

After cleaning, it’s vital to rinse thoroughly with fresh water to remove any remaining detergent residue. This step is crucial because leftover soap can attract dirt and moisture, which may lead to further corrosion down the line. Finally, applying a protective coating after neutralizing any existing corrosion will help fortify your aluminum against future attacks from salty environments.

Scheduled Maintenance Practices

In addition to regular cleaning and inspections, developing scheduled maintenance practices can significantly extend the life of your aluminum assets in marine settings. Consider setting up quarterly check-ups where you assess both aesthetic elements (like paint) and functional components (like fittings). This proactive approach allows you to stay ahead of potential problems related to how long do aluminum cans last in saltwater or other similar concerns.

During these scheduled practices, look out for signs like discoloration or flaking paint; these could indicate underlying issues that need immediate attention. Moreover, keeping records of maintenance activities helps track what works best for protecting metal from saltwater over time—knowledge is power! With diligent care and attention paid regularly, you’ll ensure that your aluminum remains strong against harsh conditions.

Physical Barriers to Corrosion

The Use of Sacrificial Anodes

Sacrificial anodes are a tried-and-true method for how to protect aluminum from saltwater corrosion. These anodes are made of a more reactive metal, such as zinc or magnesium, which corrode preferentially when submerged in saltwater. By sacrificing themselves, these anodes effectively protect your aluminum components and can increase their longevity in harsh marine conditions.

But how do you know if your sacrificial anodes are doing their job? Regular inspections are key; if they’re significantly corroded or depleted, it's time for a replacement. This proactive approach not only answers the question Can aluminium withstand salt water? but also ensures that your metal remains safeguarded against the ravages of corrosion.

Installing Protective Barriers on Boats

Installing protective barriers on boats is another effective strategy for keeping aluminum safe from saltwater exposure. These barriers can take many forms—such as coatings, wraps, or even physical shields—that act as a buffer between your boat's hull and the corrosive elements present in seawater. By creating this separation, you can greatly reduce the risk of corrosion and answer concerns about how to protect metal from salt water effectively.

Moreover, these protective installations should be part of regular maintenance checks; ensuring they remain intact will help you avoid costly repairs down the line. If you're wondering about how long do aluminum cans last in saltwater when properly protected by these barriers, you'll be pleased to know that they can last significantly longer than those without any safeguards!

Weisidun Yacht's Solutions for Marine Protection

Weisidun Yacht offers innovative solutions tailored specifically for protecting aluminum from the harsh realities of marine life. Their products focus on advanced coatings and sacrificial anode systems designed to neutralize salt corrosion effectively while enhancing durability. Not only do these solutions address how do you neutralize salt corrosion on aluminum?, but they also provide peace of mind for boat owners concerned about longevity.

In addition to their cutting-edge technology, Weisidun emphasizes user education; understanding how to maintain and install these products is crucial for achieving optimal results. Investing in such specialized protection means that your vessels will have greater resilience against environmental challenges while allowing them to shine brightly amidst salty waves! With proper care and attention using Weisidun's solutions, you'll ensure that your investment stands strong against time and tide.

Long-Term Durability in Saltwater

How Long Do Aluminum Cans Last in Saltwater?

You might be wondering, how long do aluminum cans last in saltwater? The answer isn't straightforward, as it depends on several conditions including water temperature and exposure time. Generally speaking, an aluminum can may last anywhere from a few months to several years before significant corrosion sets in; however, this timeline can vary widely based on environmental factors and protective measures taken.

Interestingly enough, while aluminum itself is relatively resistant to corrosion due to its protective oxide layer, this layer can be compromised by prolonged exposure to salty water. So if you're asking yourself: can aluminium withstand salt water? The short answer is yes—if properly protected and maintained—but neglecting care can lead to rapid degradation over time.

Factors Affecting Longevity in Marine Environments

Several factors affect the longevity of aluminum products exposed to marine environments. These include salinity levels, temperature fluctuations, and even biological factors like algae growth or barnacle attachment that could exacerbate corrosion rates. Understanding these variables is essential for anyone looking for effective ways on how to protect metal from salt water.

For instance, higher temperatures typically increase the rate of chemical reactions that lead to corrosion; therefore, keeping your aluminum structures cool could extend their lifespan significantly. Additionally, regular maintenance practices such as cleaning and inspections play a vital role in ensuring that protective coatings remain intact and effective against corrosive elements found in seawater.

Storage and Handling Tips

To maximize your aluminum's lifespan when dealing with saltwater conditions, proper storage and handling are key components of your strategy on how do you neutralize salt corrosion on aluminum? When not in use or during off-seasons for boats or marine equipment, storing items indoors or covered will help shield them from harsh environmental elements.

Regularly cleaning your aluminum products with fresh water after they've been exposed to salty conditions is another excellent tip for maintaining their integrity over time. Furthermore, consider using protective coatings such as marine paints or anodizing treatments before storage; these methods will provide an added layer of defense against future corrosive encounters.

Conclusion

In summary, protecting aluminum from saltwater is crucial for maintaining its integrity and longevity. By understanding the various forms of corrosion that can affect aluminum, we can take informed steps to ensure that our metal remains in top condition. From effective protective coatings to regular maintenance practices, there are numerous strategies available to combat the harsh marine environment.

Key Takeaways on Protecting Aluminum

To effectively protect aluminum from saltwater, it’s essential to use appropriate coatings and maintenance techniques. Regular cleaning and inspections play a vital role in identifying early signs of wear or corrosion, allowing for timely intervention. Remember, while the question Can aluminium withstand salt water? may seem straightforward, the answer often hinges on proactive care and protection measures.

Innovations in Marine Protection

Recent advancements in marine protection have led to innovative products designed specifically for aluminum structures exposed to saltwater. These include advanced marine paints with enhanced durability and new anodizing processes that offer superior resistance to corrosion. As we explore how to protect metal from salt water further, these innovations promise not only better performance but also longer-lasting results.

Future Trends in Aluminum Durability

Looking ahead, the future of aluminum durability in marine environments appears bright thanks to ongoing research and development efforts focused on corrosion resistance. New materials and technologies are being developed that enhance how long do aluminum cans last in saltwater while minimizing environmental impact. As we continue exploring solutions for how do you neutralize salt corrosion on aluminum?, it’s clear that staying informed about these trends will be essential for anyone working with aluminum in coastal areas.